Annealing is a warmth therapy procedure that involves heating a material to a particular temperature level where atomic flexibility rises, permitting the relief of internal tensions, decrease of solidity, and improvement of ductility. This home heating is normally complied with by a sluggish air conditioning process, which can take place in a heater or in ambient air, relying on the preferred metallurgical framework. The first home heating temperature varies based on the material being treated but typically range from red to orange heat on a shade range, usually around 600 ° C to 900 ° C for several alloys. This procedure properly modifies the microstructural structure of the metal, allowing the arrangement of atoms to redistribute themselves into a state of lower energy. Because of this, the steel presents enhanced gentleness, improved machinability, and enhanced overall mechanical efficiency. Usual steels going through annealing include steel, light weight aluminum, and copper, where the variants of annealing-- such as full annealing, process annealing, and spheroidizing-- yield various outcomes based on the specific demands of the application.

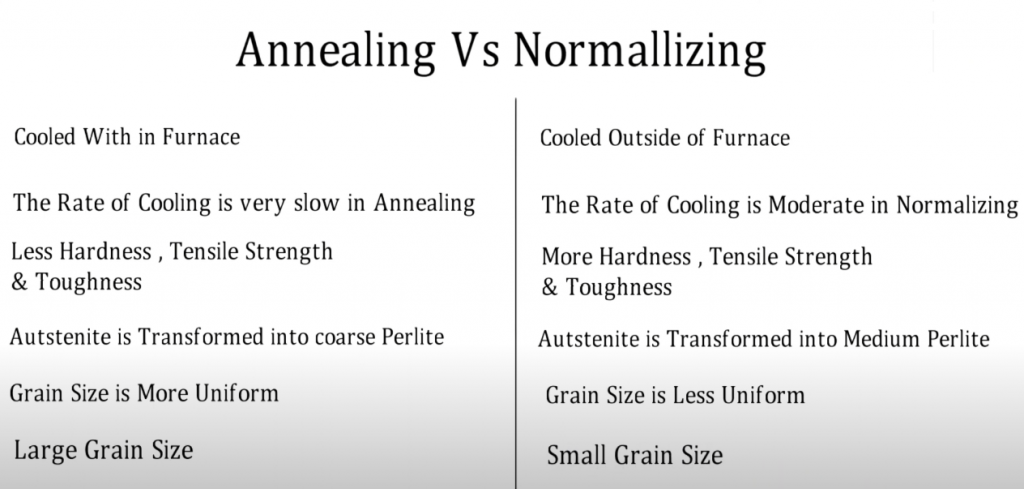

In comparison, normalizing is likewise a heat therapy procedure but is largely utilized to refine the grain framework of a metal and achieve an uniform and wanted mechanical residential property throughout. It involves heating the steel to a temperature above its essential variety, generally 30-- 50 ° C over the upper important temperature level, before allowing it to cool off in air. This air-cooling rapidity differentiates stabilizing from annealing, as it not only changes the microstructure but additionally introduces a special refinement of the grain dimension, resulting in far better strength and toughness. The process gain from a higher air conditioning rate, which influences the final microstructure, leading to a finer and more consistent arrangement of grains contrasted to metals treated with annealing. It is a particularly reliable treatment for ferrous alloys, such as carbon steels, where accomplishing high-performance material homes like yield stamina and tensile toughness is often needed for industrial applications. Normalized iron and steel normally exhibit remarkable mechanical properties when contrasted to their annealed equivalents, highlighting the role of cooling down price in determining material attributes.

Discover annealed vs normalized the important distinctions in between annealing and normalizing in metallurgy, two crucial heat treatment procedures that considerably influence the mechanical buildings and performance of steels and alloys in numerous applications.

While both processes share resemblances, they are picked based on the certain properties needed for a classification or application of the material. For example, in making procedures where improved mach failure, good formability, or improved ductility is desirable, products are more probable to undertake annealing. On the other hand, when the target qualities rotate around raised toughness, rigidity, or stamina, stabilizing is usually the preferential treatment. This divergence in purpose underlines an understanding of metallurgy, making certain that the therapy procedure straightens with the anticipated specifications and service conditions of the application.

Throughout numerous sectors, annealing and stabilizing serve significant roles. As an example, in the automotive sector, while several parts are made via creating or casting, subsequent heat therapies are essential. Annealing is regularly made use of for steel components, such as equipments and shafts, to improve resistance against brittle fracturing, which might emerge from welding procedures or operational strains throughout their life span. Likewise, normalizing locates considerable applications in architectural elements for buildings and machinery, where the improvement of mechanical residential properties under packing conditions is of utmost importance. This microstructural refinement promotes improvements in yield toughness and durability, consequently prolonging the lifespan and efficiency capacities of these products.

Both warmth therapy processes also highlight the equilibrium in between achieving wanted physical residential properties and optimizing performance. As an example, the time and power prices associated with each treatment develop a surge impact in manufacturing performance and output. Annealing needs mindful tracking of temperature and time to make sure a beneficial therapy without excessive over-softening, while normalizing, many thanks to quicker cooling times in air, frequently enables decreased downtime in manufacturing routines. Both processes need careful factors to consider not only for attaining optimal microstructure however also for incorporating well within the assembly line, eventually impacting economic stability and sustainability.

The intricacies of annealing versus normalizing locate relevance in research study and academic community, where a much deeper understanding of materials can lead to improvements in design practices. For instance, in light-weight yet durable applications, such as vehicle and aerospace elements, the critical application of various warm therapies can dramatically influence material option. Study efforts typically dive right into the end results of both processes and develop enhanced techniques that mix treatment techniques, enabling cutting-edge remedies that meet the ever-evolving demands of contemporary sectors.

One have to also emphasize the environmental effects bordering making use of heat treatments like annealing and normalizing. With growing understanding of sustainability and energy effectiveness within producing procedures, initiatives are underway to minimize the ecological impact of these standard approaches. Technologies in heat treatment innovations, consisting of the growth of more efficient furnace and optimization of cycle times, play an important duty in lowering emissions and power consumption. Engineers and researchers are actively going after means to make therapy approaches greener, assessing power usage throughout procedure cycles, and incorporating renewable resource sources where possible. This shift towards more lasting methods not just highlights the significance of annealing and normalizing in generating premier products yet emphasizes the demand to boost sector criteria past plain mechanical performance and right into ecological stewardship.

In terms of residential property comparisons, annealed and normalized materials supply unique advantages owing to their integral microstructural attributes. This divergence brightens the delicate interaction between microstructure and the final features of a material, making it important for professionals in metallurgy or design to assess their options with both approaches in mind.

As innovations in materials scientific research continue to progress, the interaction between procedures affects the research study and development of brand-new alloys and composites. Scientists are frequently checking out mixes and additives that change thermal treatment procedures, leading to the design of innovative products that display unique performance attributes.

Summarizing the differences in between annealed and normalized metals communicates a fascinating narrative of basic science, functional application, and recurring development in product studies. In comprehending these important processes within warmth treatment, experts rally a much deeper comprehension that offers not only their instant duties however adds to broader development throughout industries. Whether it is supplying devices for safer facilities, developing efficient vehicle parts, or pioneering the design of products for the future, the study of annealing and normalizing will definitely be a keystone topic, connecting the expertise of materials, the technical experience of engineers, and the development of sector standards for many years to find. As the intricacies of the material world will constantly give challenges, the mastery of annealing and normalizing processes will certainly be important, making sure the toughness and sustainability of engineered components. Each method adds distinctly to our material landscape, and understanding their differences is crucial for those who seek to master the areas of metallurgy and products scientific research. Via these insights, we cultivate a future where the principles rooted in these thermal treatments assist us towards cutting-edge solutions and resilient applications that resonate throughout all fields of culture, thereby solidifying the vital value of these procedures in our everyday lives.